Category Archive Slideshow

- Home /

- Archive by category "Slideshow"

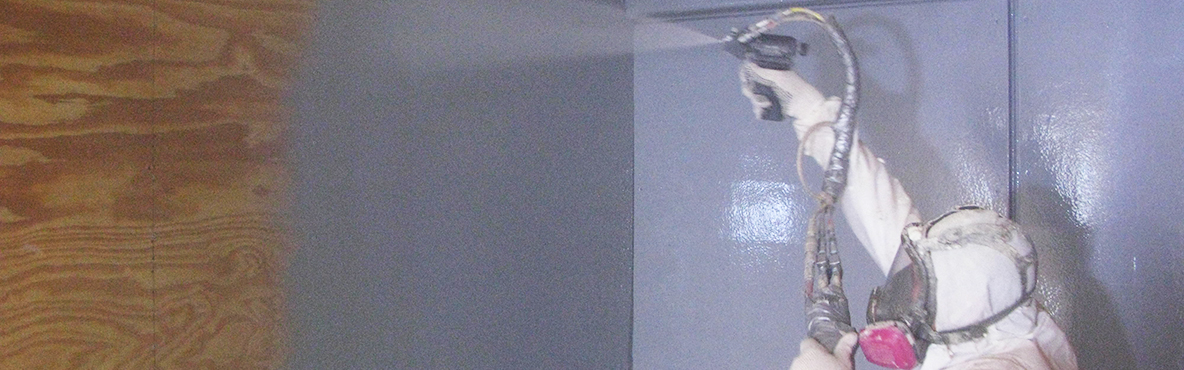

Spray Foam Insulation

LSC Spray Foam Division

Spray Polyurethane Foam (SPF) or spray foam insulation is our specialty within the insulation division here at Lone Star Contracting (LSC). Since our certified sprayers manufacture and install our plural component system on site, you get a certified team who fully understands not only the product they are spraying but the science behind the application techniques and methods. With our dual proportioner mobile spray rigs we always have a minimum of two applicators spraying at the same time ensuring that we will finish your building on time, and on budget.

Spray Polyurethane Foam (SPF) or spray foam insulation is our specialty within the insulation division here at Lone Star Contracting (LSC). Since our certified sprayers manufacture and install our plural component system on site, you get a certified team who fully understands not only the product they are spraying but the science behind the application techniques and methods. With our dual proportioner mobile spray rigs we always have a minimum of two applicators spraying at the same time ensuring that we will finish your building on time, and on budget.

For more information, please call 325-617-4521 or fill out the form below:

We’re not your low budget, fly-by-night, working out of a garage, price-slashing kind of company. We take pride in our jobs and stand behind them 110%!

Some key attributes of spray foam:

- Expands to get into every single void in your building, combining sealing and insulating into one simple step

- Maintains its durable consistency over time without sagging or settling, so you get the same energy savings year in and year out

- Provides a complete air seal for maximum energy efficiency

- Resistant to moisture and mold growth, and is not a food source for rodents and insects

- Although we’re known for larger projects our services are perfect for just about any job you have, whether it’s residential, commercial, or industrial.

Here are the areas where our services work best:

Government & Industrial Facilities

Government and industrial projects often come with unique sets of specifications. LSC’s extensive experience with insulating these types of facilities ensures that we will finish your building on time, and on budget.

Government and industrial projects often come with unique sets of specifications. LSC’s extensive experience with insulating these types of facilities ensures that we will finish your building on time, and on budget.

Our insulation and expertise have been used in a wide variety of jobs, including:

- Libraries

- Medical Facilities

- Community Centers

- Parks & Recreational Facilities

- Public & Private Educational Facilities

Commercial & Corporate Facilities

Our staff’s experience and expertise is a perfect match for your commercial or corporate project — especially when we use spray foam insulation. We’ll make sure that you get the highest possible energy savings and comfort from your building.

Our staff’s experience and expertise is a perfect match for your commercial or corporate project — especially when we use spray foam insulation. We’ll make sure that you get the highest possible energy savings and comfort from your building.

Our insulation and expertise have been used in a wide variety of jobs, including:

- Retail stores

- Hotels

- Office buildings

- Medical facilities

- Restaurants

New Residential Construction

LSC has proven expertise and experience with new home construction. Over the years, we’ve worked with premier homebuilders, so we know firsthand what it takes to get the job done right — and how to give the builder and the homeowner everything they need for great project results.

LSC has proven expertise and experience with new home construction. Over the years, we’ve worked with premier homebuilders, so we know firsthand what it takes to get the job done right — and how to give the builder and the homeowner everything they need for great project results.

Air Sealing

Before we do any insulating, we’ll take all the steps necessary to make sure the area we’re about to treat is properly prepared. This is more than just covering things up with plastic – it’s a comprehensive process that always includes these steps:

- Protect all mechanicals, doors, windows, and any finished surfaces

- Caulk all penetrations

- Foam windows and doors

- Caulk all sills, t-walls, corners, double- and triple-studs, windows, and door headers

Fiberglass Insulation

Wool-type fiber glass is most commonly used as insulation in all types of buildings, from homes to commercial to industrial. Its unique properties make it work well for controlling temperature and sound.

- Utilizes tiny pockets of air to effectively resist the flow of heat and cold

- Comes in widths suited to standard spacing of wall studs, attic joists, and floor joists

- Available with facings, which add additional protection from vapor, unwanted air flow, and fire

Blown-In Insulation

Blown-in (a form of loose fill) insulation is named for the installation process, which involves using a high-pressure blowing machine and a hose to distribute the insulation into the building. Our blown-in insulation is made of fiberglass, giving it advantages over other loose fill insulation materials.

- Works well for hard-to-reach places

- Fire-retardant without the use of corrosive chemicals

- Resistant to moisture and mold growth, and is not a food source for rodents and insects

|

|

|

|

|

|

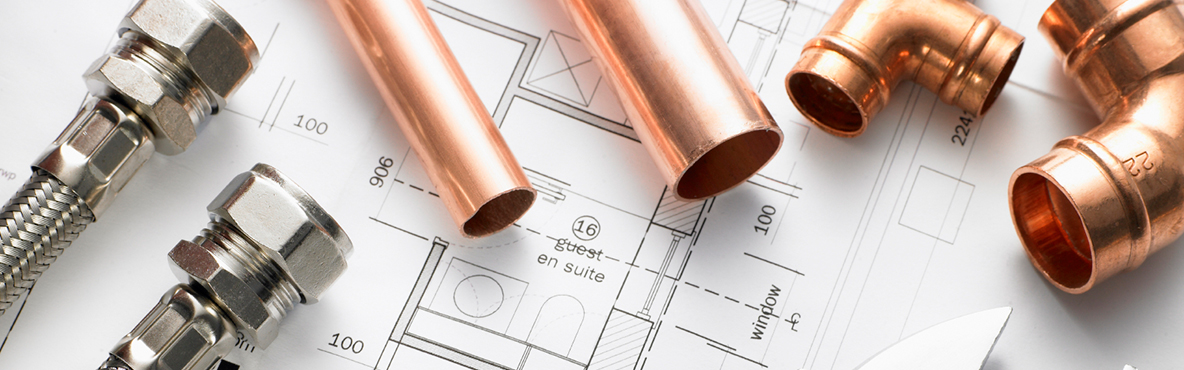

Commercial & Residential Plumbing

Lonestar Contracting Plumbing Division

Lone Star Contracting (LSC) has provided plumbing solutions to customers throughout West Texas since 2004. Our expertly trained plumbers are specialists in diagnosing and solving all types of plumbing problems. LSC provides the quality materials and professional workmanship you deserve. Our licensed journeymen, most of whom have been with our company for at least 5+ years, assure that each project will be completed in a timely, organized manner, and to proper codes.

Call Lone Star Contracting (LSC) at (325) 617-4521 to speak with a plumbing professional about any plumbing project including water and gas piping, water treatment, water heater installation, water leak detection, drain cleaning and system repairs, or fill out the contact form below:

LSC Commercial/Residential Service

LSC is capable of tending to all your plumbing needs. Our skilled plumbers are equipped with all the latest plumbing technology and methods. Let our skilled plumbers solve your plumbing problems quickly and efficiently. No job is too big or too small. We have been the primary

LSC is capable of tending to all your plumbing needs. Our skilled plumbers are equipped with all the latest plumbing technology and methods. Let our skilled plumbers solve your plumbing problems quickly and efficiently. No job is too big or too small. We have been the primary ![]() provider for San Angelo and the surrounding areas since 2012 serving thousands of customers.

provider for San Angelo and the surrounding areas since 2012 serving thousands of customers.

Every member of our team values the importance of great customer service. We do our best to provide a friendly and pleasant experience for all of our customers. We are not just there to do a job and drive off to the next project. Our team seeks to educate our customers and provide top-notch advice you can use to make sure your plumbing system experiences minimal problems over time.

LSC Commercial New Construction

At LSC, we specialize in the installation of plumbing mechanical systems in schools, churches, apartment complexes, assisted living centers, restaurants, office buildings, strip malls, dental and doctors’ offices, and similar commercial facilities in the West Central Texas area. If your project requires design/build services, we work closely with a mechanical engineer to design a system to meet your requirements. That coupled with our ability to value engineer any project to help our contractors/customers bring their projects in on or under budget!

At LSC, we specialize in the installation of plumbing mechanical systems in schools, churches, apartment complexes, assisted living centers, restaurants, office buildings, strip malls, dental and doctors’ offices, and similar commercial facilities in the West Central Texas area. If your project requires design/build services, we work closely with a mechanical engineer to design a system to meet your requirements. That coupled with our ability to value engineer any project to help our contractors/customers bring their projects in on or under budget!

LSC Residential New Construction

No matter how large or small your new home or building will be, we are equipped to service your new construction plumbing needs. We employ leading–edge equipment and practices to make installation of your sewer, water, and gas systems efficient and practical. Please call or email us for a new construction plumbing consultation.

No matter how large or small your new home or building will be, we are equipped to service your new construction plumbing needs. We employ leading–edge equipment and practices to make installation of your sewer, water, and gas systems efficient and practical. Please call or email us for a new construction plumbing consultation.

Professional Associations, Awards and Certifications

- Plumbing Contractors License, #M-36987

- Plumbing, Heating and Cooling Contractors Association

- Railroad Commission of Texas

- OSHA Safety Training Certified

- National Safety Council

- San Angelo Chamber of Commerce

- Better Business Bureau

Promotions and Special Offers

- We Offer a Senior Citizen and Military Discount!

Specialties

- Founded in 2004

- Experts in our field

- Commercial and Residential Service

- Easy Water No-Salt Conditioning

- Sewer Video Camera Inspection

- Hydro Jet Drain Cleaning Service

- Drug-Free Workplace

- Educational Assistance Program for Employees

- Supporting a Variety of Community Organizations

Swimming Pools

LSC Fiberglass Pool Division

Lone Star Contracting (LSC) has provided fiberglass swimming pools to customers in San Angelo and the surrounding areas since 2006. We are proud to offer our customers the finest fiberglass pools manufactured today. We have the experience, expertise, and know how to make your project a success. So allow us to transform your backyard into that dream vacation paradise for you and your family to enjoy for years to come.

Lone Star Contracting (LSC) has provided fiberglass swimming pools to customers in San Angelo and the surrounding areas since 2006. We are proud to offer our customers the finest fiberglass pools manufactured today. We have the experience, expertise, and know how to make your project a success. So allow us to transform your backyard into that dream vacation paradise for you and your family to enjoy for years to come.

For more information, call 325-617-4521 or fill out the form below:

Why Fiberglass Swimming Pools?

1. Speed of Installation

1. Speed of Installation

Your fiberglass swimming pool comes direct from the Leisure Pools manufacturing facility, pre-made and ready to install. In fact, you can be swimming in as little as 7 days after your pool arrives. Compare that to a concrete pool that can take months to complete and during that time your backyard looks a mess!

2. Smooth Finish

Leisure Pools fiberglass swimming pools have a smooth clean gelcoat finish that is non-abrasive. There are no sharp edges or rough finishes. Compare that to the plaster or pebble finish on Gunite pools that are so abrasive they can harm your skin.

3. Maintenance Free

The gelcoat finish on a Leisure Pool not only looks great, its so easy to look after. The surface is smooth and non-porous so it cleans easily and is extremely stain resistant.

4. Low Chemical Usage

No one likes swimming in a chemical cocktail but some pools require constant monitoring and expensive chemicals. Not so with Leisure Pools fiberglass, the surface is chemically inert so there is nothing in the pool surface that can alter the water chemistry. Hence, very low chemical usage and considerable cost savings on running your pool.

5. Surprising Strength

5. Surprising Strength

Leisure Pools fiberglass pools exceed the Australian Standards for shell thickness. The high tensile strength of fiberglass will allow the pool shell to flex without cracking to accommodate earth movement.

6. Great Designs

Leisure Pools prides itself on being at the cutting edge of pool design technology. All of our swimming pool shapes are new designs and reflect today’s thinking and architectural trends. There will be a Leisure Pools design to ideally suit your home.

7. Color Range

Leisure Pools offers an exclusive range of seven beautiful colors, each with its own sparkle and shimmer finish, ensuring you will be able to find the perfect color to suit your home, taste and budget.

8. The Right Choice

Some times what we see in our minds doesn’t always translate to the pool builder. With Leisure Pools fiberglass swimming pools, what you see is what you get. The swimming pool shapes and sizes come off molds and cannot vary in anyway.

9. Compatibility

Salt chlorinators, chlorine, fresh water systems, ozone systems all work wonderfully well with Leisure Pools fiberglass swimming pools. Whatever your choice may be it will be compatible.

10. Warranty

10. Warranty

If you are getting other quotes, ask if a lifetime warranty is being provided on the structure of the swimming pool. At best with a concrete swimming pool you will get a 7 year warranty – do you hope to have your pool longer than 7 years?

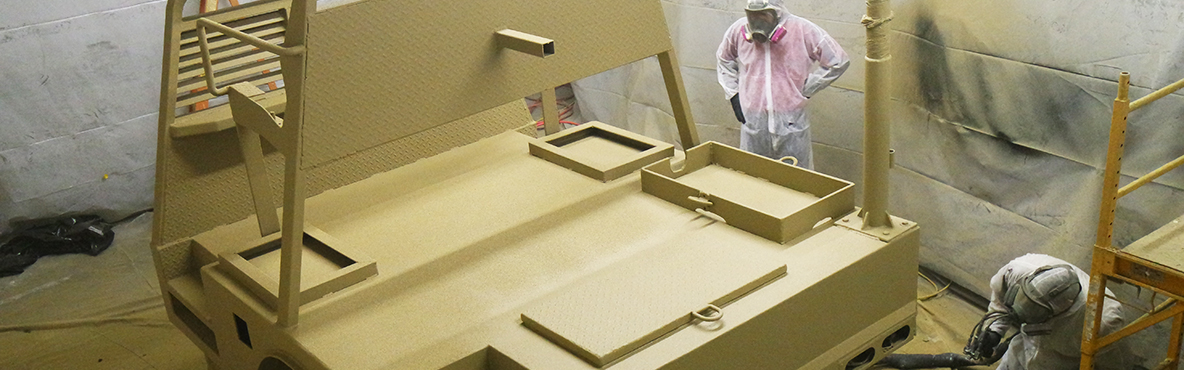

LSC Coatings Division

LSC Coatings Division

The coatings division of Lone Star Contracting (LSC) is our company’s newest division and Polyurea is the product of choice because of its remarkable coating, lining and joint sealant capabilities. Today, it is being used successfully for many different applications.

The coatings division of Lone Star Contracting (LSC) is our company’s newest division and Polyurea is the product of choice because of its remarkable coating, lining and joint sealant capabilities. Today, it is being used successfully for many different applications.

For more information, call 325-617-4521 or fill out the form below:

Polyurea coatings and linings are more commonly known to be applied over concrete and steel for corrosion protection and abrasion resistance. Protective coatings and linings also have tremendous advantages over conventional materials for joint fill and caulk applications due to their fast set nature, high elongation and durability/abrasion characteristics.

Polyurea coatings and linings are more commonly known to be applied over concrete and steel for corrosion protection and abrasion resistance. Protective coatings and linings also have tremendous advantages over conventional materials for joint fill and caulk applications due to their fast set nature, high elongation and durability/abrasion characteristics.

Common uses for Polyurea protective coatings:

• Abrasion Resistance

• Corrosion Protection

• Waterproofing

• Chemical Resistance

• Environmental Resistance

• Wind uplift resistance

• Atmospheric Resistance

• Decoration

• Structural Enhancement

Whether you require waterproofing or protection we offer a one-stop prep and coating service for almost any application. Our concrete coatings are tough enough for the most demanding industrial environments and offer high levels of chemical resistance, elongation and impact protection. Our steel coatings offer protection from extreme impact and abrasion meaning chipping and flaking is a thing of the past.

Whether you require waterproofing or protection we offer a one-stop prep and coating service for almost any application. Our concrete coatings are tough enough for the most demanding industrial environments and offer high levels of chemical resistance, elongation and impact protection. Our steel coatings offer protection from extreme impact and abrasion meaning chipping and flaking is a thing of the past.

Our Polyurea know-how and equipment makes us one of West Texas’s most well equipped applicators. Our purpose built mobile spray unit is capable of undertaking the largest of on-site spray work.

Our Polyurea know-how and equipment makes us one of West Texas’s most well equipped applicators. Our purpose built mobile spray unit is capable of undertaking the largest of on-site spray work.

Unlike many contractors who carry their spray equipment in multiple vehicles and spend hours setting up the equipment before spraying can commence our mobile unit requires nothing more than a turn of the key due to all our equipment being permanently fixed including generator, air compressor, Polyurea reactor and the maximum length of hose.

Unlike many contractors who carry their spray equipment in multiple vehicles and spend hours setting up the equipment before spraying can commence our mobile unit requires nothing more than a turn of the key due to all our equipment being permanently fixed including generator, air compressor, Polyurea reactor and the maximum length of hose.